Electrical & Instrument

T2000 – I/P or Input/Signal to Pressure Transducer

T2000 – I/P or Input/Signal to Pressure Transducer

The BelGAS type t2000 Input/signal to Pressure transducer uses a closed-loop pressure feedback system for precision pressure output and minimal environment effects.

Product Highlight

Options / Features

- High precision, 0.1% accuracy typical

- Vibration and position insensitive

- DIP switches permit field selection of inputs and direct / reverse / split ranging

- Very wide selection of input and output ranges

- NEMA 4X (weatherproof) and intrinsically safe are standard

- Explosion proof model available

- 140 psig max pressure input

Specialty MFCS

Specialty MFCS

DIGITAL / SPECIALTY MFCS

Models

- MicroTrak 101 Ultra Low Flow

- SmartTrak 140 Ultra Low Delta P

- SmartTrak 100-HP Ultra High Pressure

- MaxTrak 180 Industrial NEMA 6 (IP67)

Description

- Digital MFC’s engineered for challenging applications

- Ultra-low flow rates down to 0.1 sccm (smlm)

- Ultra-low pressure drop ΔP of 5 psid (310 mBard)

- Industrial approval ratings of NEMA 6 & IP67 ratings

- High pressure up to 5000 psig (345 barg)

- Many other versions available, consult factory

- Leak integrity 5 x 10-9 smL/sec of helium

- Free user software

- CE Approved

Fluids Measured

- All clean gases including toxics and corrosives

Smarttrak 100

Smarttrak 100

DIGITAL / SMARTTRAK 100

Models

- 100L Low Flow

- 100M Medium Flow

- 100H High Flow

Description

- Highest performance multi-gas MFC

- Flagship mass flow meter & controller

- Navigate easily with large multifunction display interface

- Free user software

- Primary Standard calibration & NIST traceability

- Make adjustments in the field

- Configure up to 10 gasses

- Proprietary frictionless-hovering, direct- acting control/shut-off valve

- User-friendly pilot module display interface is front-mounted, hand-held, or remote mounted

- Leak integrity 5 x 10-9 smL/sec of helium

- CE Approved

Fluids Measured

- All clean gases including toxics and corrosives

- Dial-A-Gas allows you to change between 10 gases with one unit

Smarttrak 50

Smarttrak 50

DIGITAL / SMARTTRAK 50

Models

- 50L Low Flow

- 50M Medium Flow

Description

- Economical digital mass flow meter and controler

- Powerful digital high-performance at OEM pricing

- Save money with volume discounts

- Navigate easily with large display

- Free user software

- Choice of aluminum or 316 stainless steel construction

- Compact size makes drop-in replacement easy

- Local display and digital setpoint

- Optional analog setpoint/output signals

- Field adjustable zero and span

- Primary Standard calibration & NIST traceability

- Leak integrity 1 x 109 smL/sec of helium

- CE Approved

Fluids Measured

- All clean gases including toxics and corrosives

Controller

Controller

The Smart Belt Scale is connected to a BFC electronic controller – panel or wall version

Product Highlight

Standard

- 3 configurable isolated digital outputs with programable thresholds: totalizer, alarm, horn

- 1 configurable isolated 0/4-20 mA analog output for either: flowrate, current weight, speed, load per meter

- 2 Configurable isolated digital inputs: out of range acknowledgement, totalizer reset

Data Links

Isolated serial communication:

- Modbus, Ethernet ModbusTCP, Profibus DP – for connection with a PLC or host computer

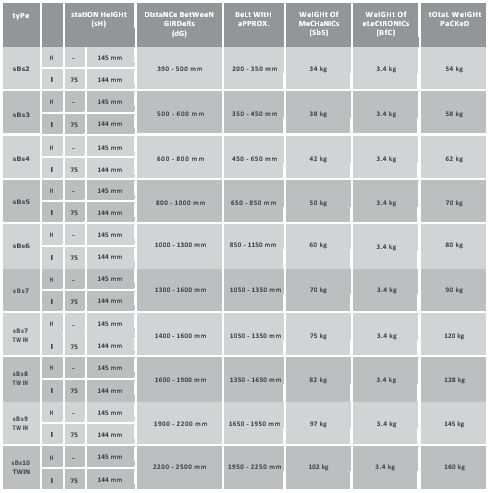

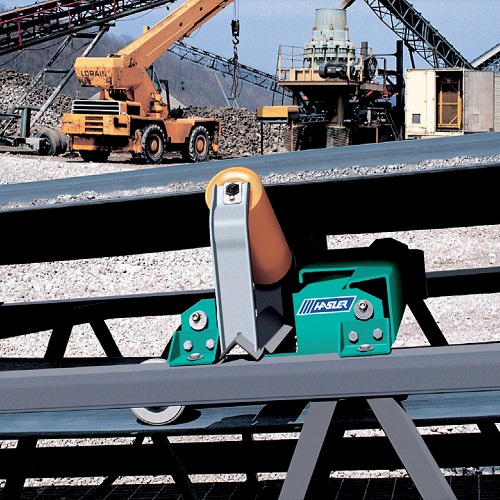

Smart Belt Scale, Single, Twin and Double (Multi-Station)

Smart Belt Scale, Single, Twin and Double (Multi-Station)

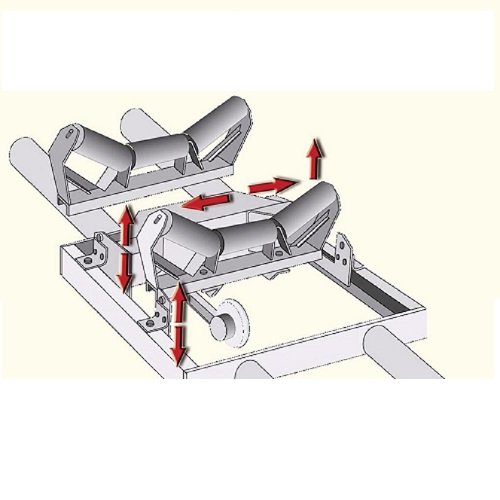

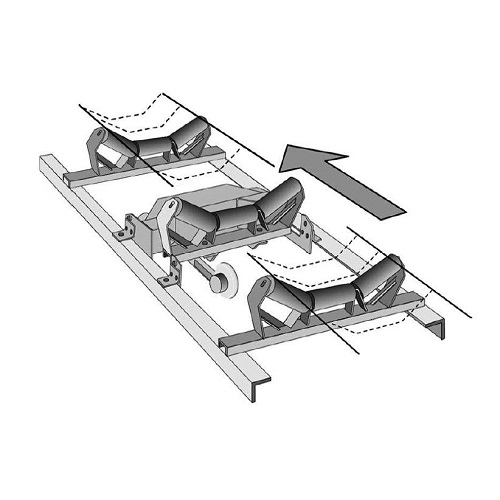

Depending on the application (high belt speed and / or flow rate), up to four single idler SBS can be combined to be used as a multi idlers belt scale. The SBS are connected to the same controller. Only one speed sensor is required, either a friction wheel speed pick-up or an incremental encoder mounted on the return drum

Conveyor Belt Scale (SBS)

Conveyor Belt Scale (SBS)

The Smart Bel Scale (SBS) is a conveyor belt scalee specially designed for rugged outdoor environment such as quarries, gravel processing and mining. It is also well suited for any manufacturing process using conveyor belts, including: cement, fertilizzer, chemical, tobacco, agro-food, etc. It is designed for easy installation which can be done by the customer’s own maintenance staff.

Product Highlight

Functions

- Weighing

- Flowrate calculation

- Totalization

- Dosing of all materials conveyed on a belt conveyor