Machinery

Oil Purification Plant

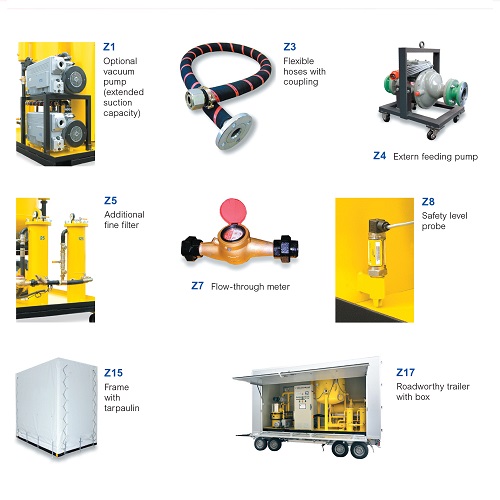

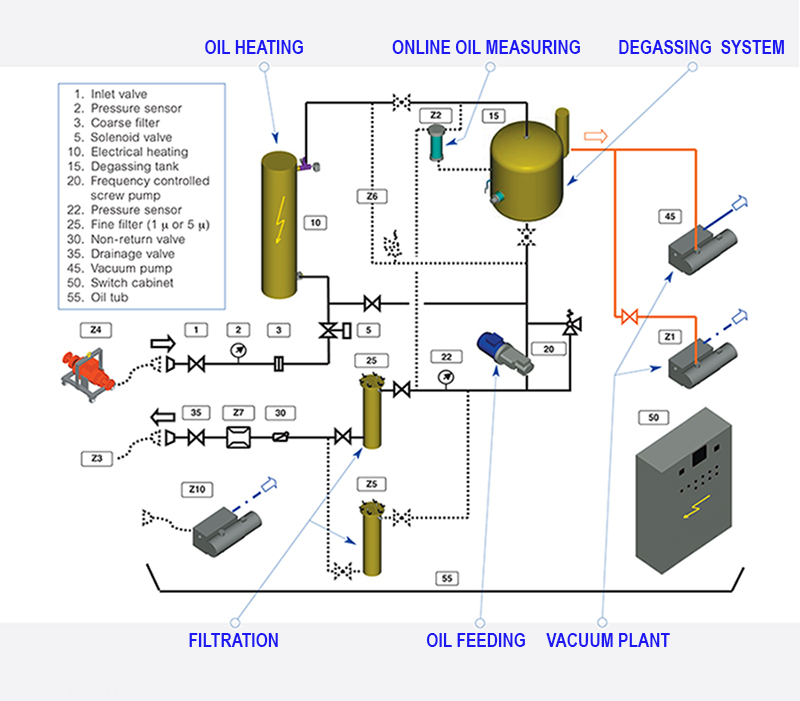

Supplements

Supplements

A large selection of supplements can be ordered together with the VOP plant. Supplements ordered at a later stage can be easily installed into the plant without refitting.

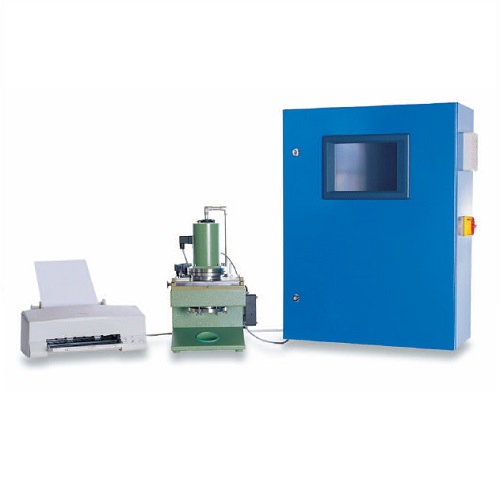

Measuring Equipments

Measuring Equipments

Mobile measuring equipment for a manifold of applications are used for estimating the insulating oil quality. The measuring equipment can be used for commonly known insulating oils. The simple and over years reliable and proven concept makes these installations maintenance and operational friendly.

Water and Gas Content Measuring Unit VZ 212 A

Water and Gas Content Measuring Unit VZ 212 A

Product Highlight

This measuring unit serves as a continuous automatic measuring of the water and gas content at the in/outlet of the oil plant. The measuring unit can only be used together with an oil plant. The evaluation of the gas blanket pressure in the measuring cell can be carried out manually by means of a break-even chart or automatically via a 6-channel digital recorder.

X-RAY

XIS-6545DV

X-RAY

XIS-6545DV

Dual View Technology Check Point Security: Baggage & Parcel Inspection

The XIS-6545DV is a dual view X-Ray Inspection System with tunnel dimensions 65 x 45 cm (25.6” x 17.7”). Designed for high threat security locales, the XIS- 6545DV is ideal for airports, government, facilities, ports, hospitals, and banks.

The XIS-6545DV features dual X-Ray generators to create two different image perspectives which can be manipulated independently. By utilizing dual view technology, alongside 6 Color Imaging and Atomic Z-Number Measurement, the XIS-6545DV provides unparalleled threat identification.

Ultimately, the XIS-6545DV dual view x ray maximizes throughput and enhances detection in locations where time efficiency and high security screening is crucial.

General Specifications

- Tunnel Size (W x H):

- 65 cm x 45 cm / 25.6” x 17.7”

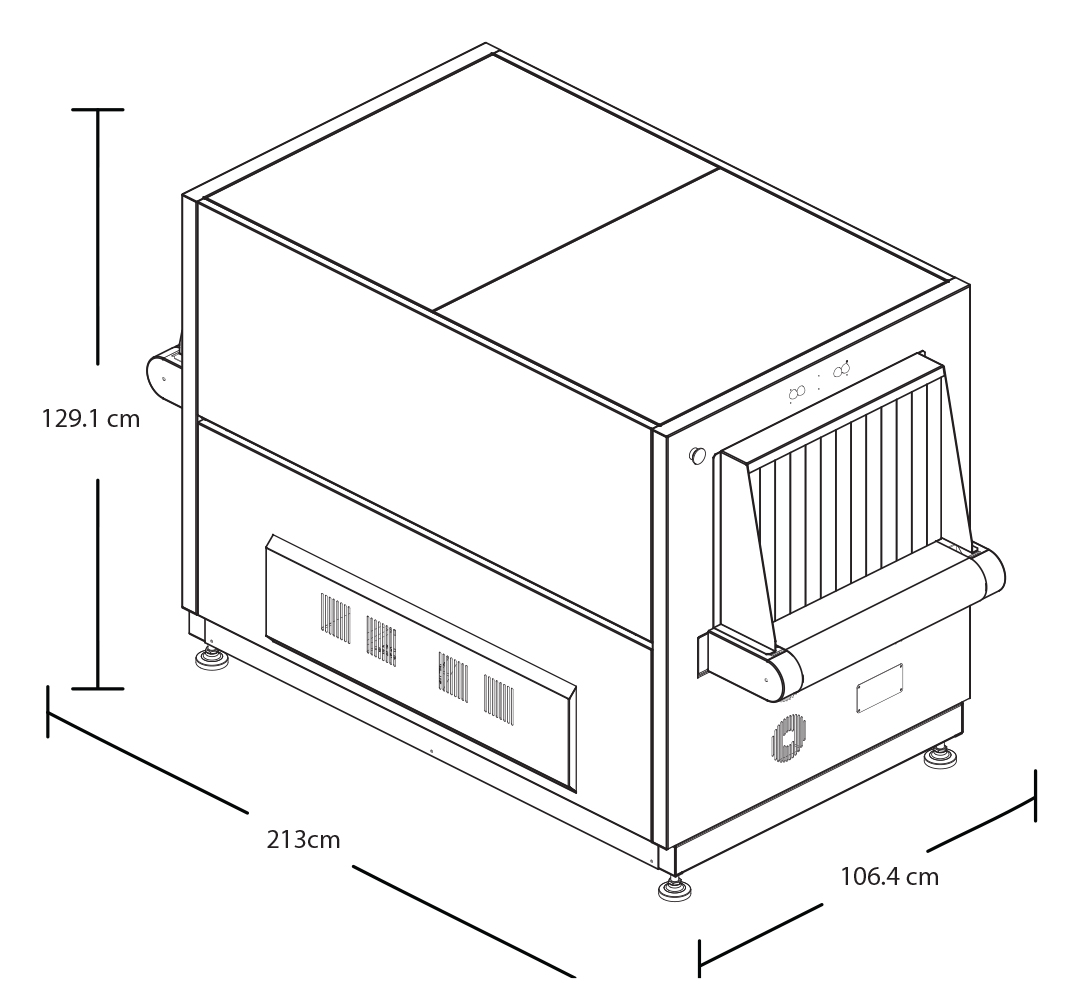

- Dimensions (L x W x H):

- 213 cm x 106.4 cm x 129 cm / 84” x 42” x 51”

- X-ray Generator:

- Dual 180kV, operating at 165 kV

XIS-100XDX

X-RAY

XIS-100XDX

Dual View Technology

Large Baggage and Parcel Inspection

The XIS-100XDX is the newest Dual View X-Ray Inspection System featuring a tunnel size of 100 cm x 100 cm (39.4” x 39.4”). The XIS-100XDX combines dual view technology with a low conveyor height of just 30 cm (12”) for optimal heavy object screening.

Dual View technology utilizes two generators, creating two image perspectives. Coupled with 6 Color Imaging, dual view technology enables operators to increase image manipulation and object recognition.

The XIS-100XDX’s low conveyor design and dual view detection enable operators to quickly scan heavy objects without any loss in threat detection accuracy.

General Specifications

- Tunnel Size (W x H):

- 100 cm x 100 cm / 39.4” x 39.4”

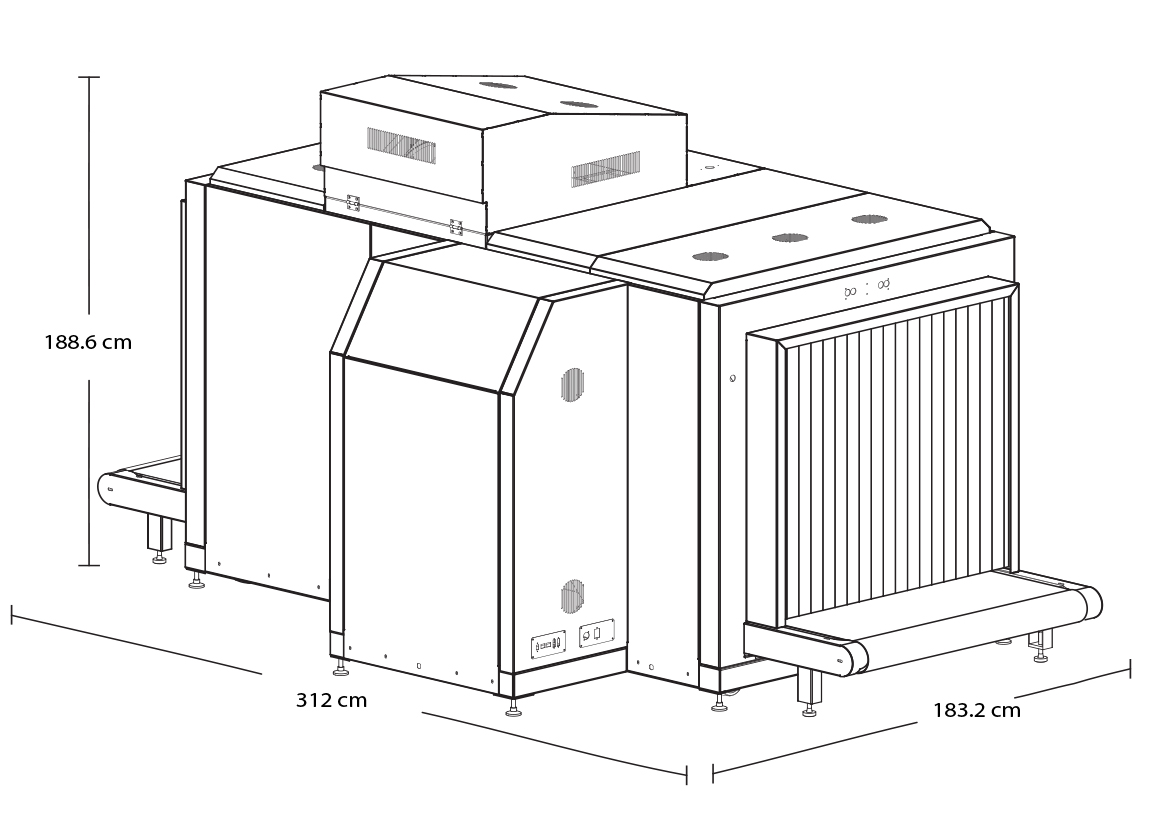

- Dimensions (L x W x H):

- 312 cm x 183.2 cm x 188.6 cm / 123” x 72.1” x 74.2”

- X-ray Generator:

- Dual 180kV, operating at 165 kV

XIS-100XDV MD

X-RAY

XIS-100XDV MD

Dual View Technology

Large Baggage and Parcel Inspection

Designed for high-threat security, the modular XIS-100XDV-MD is a dual view X-Ray Inspection System with a generous tunnel size of 101.0 cm x 101.5 cm (39.75″ x 39.97″). Based on our standard XIS-100XDV, the MD (modular design) version is built in separate modules, each with their own set of casters to allow for easy installation and integration into facillities where space may be an issue

Boosting two x-ray generators, the XIS-100XDV MD produces two screening perspectives and allows operators to manipulate each indepently, thus enhancing the operator’s ability to identify potential security threats with increased accuracy and speed. The XIS-100XDV MD is the ultimate solution for large object screening at inspection sites requiring heightened secutrity protection.

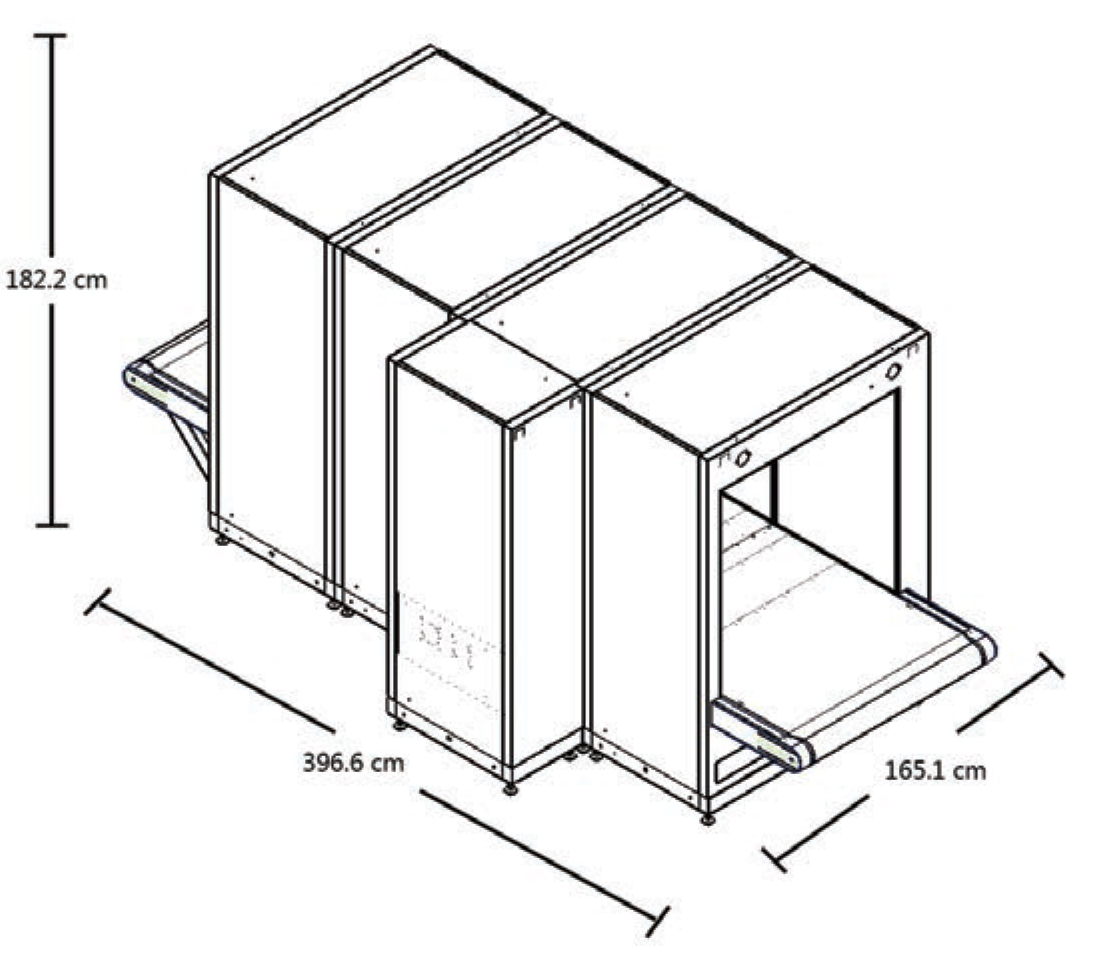

General Specifications

- Tunnel Size (W x H):

- 101.0cm x 101.5 cm / 39.75″ x 39.97″

- Dimensions (L x W x H):

- 380.7 cm x 165.4 cm x 182.2 cm / 149.87″ x 65.12″ x 71.75″

- X-ray Generator:

- Dual 180 kV, Operating at 165kV