Electrical & Instrument – HASLER

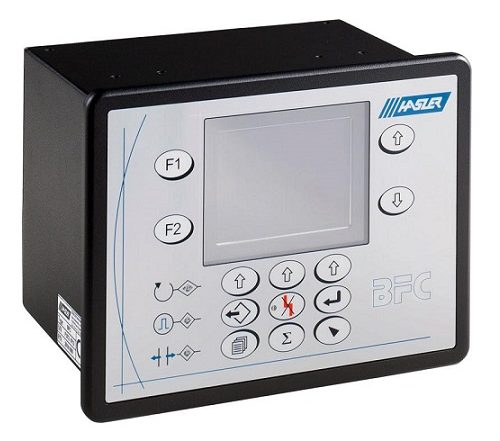

Controller

Controller

The Smart Belt Scale is connected to a BFC electronic controller – panel or wall version

Product Highlight

Standard

- 3 configurable isolated digital outputs with programable thresholds: totalizer, alarm, horn

- 1 configurable isolated 0/4-20 mA analog output for either: flowrate, current weight, speed, load per meter

- 2 Configurable isolated digital inputs: out of range acknowledgement, totalizer reset

Data Links

Isolated serial communication:

- Modbus, Ethernet ModbusTCP, Profibus DP – for connection with a PLC or host computer

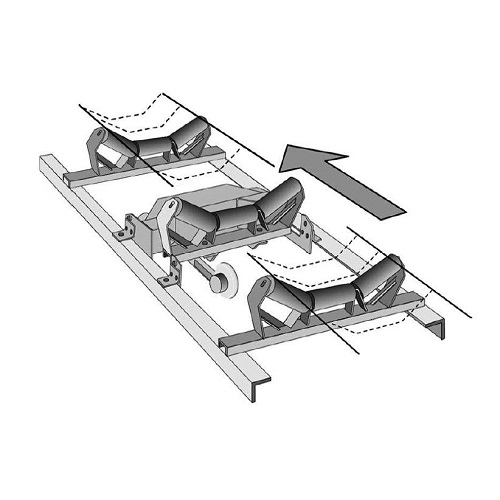

Smart Belt Scale, Single, Twin and Double (Multi-Station)

Smart Belt Scale, Single, Twin and Double (Multi-Station)

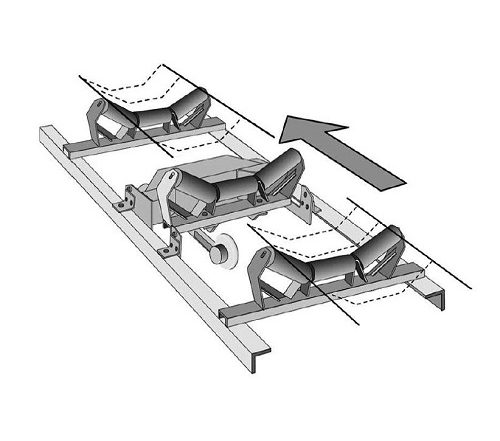

Depending on the application (high belt speed and / or flow rate), up to four single idler SBS can be combined to be used as a multi idlers belt scale. The SBS are connected to the same controller. Only one speed sensor is required, either a friction wheel speed pick-up or an incremental encoder mounted on the return drum

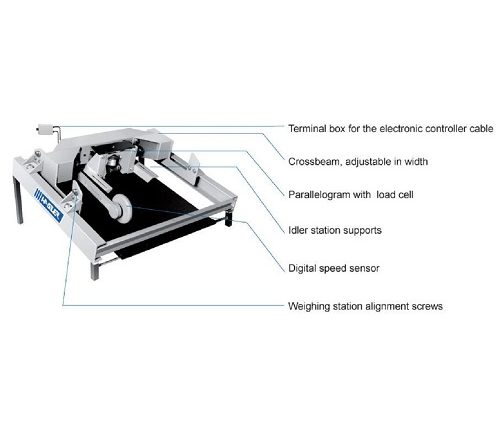

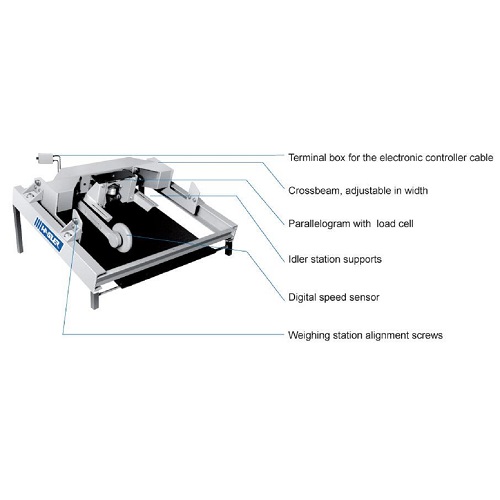

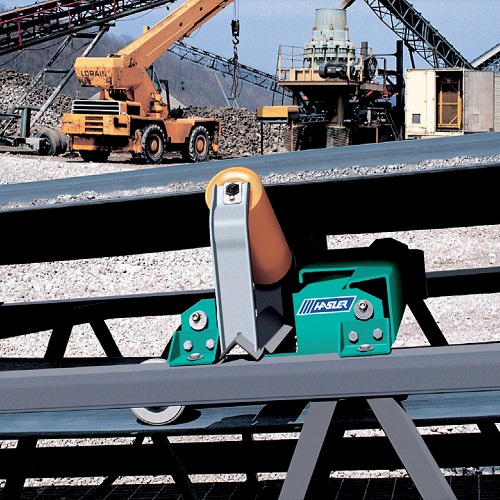

Conveyor Belt Scale (SBS)

Conveyor Belt Scale (SBS)

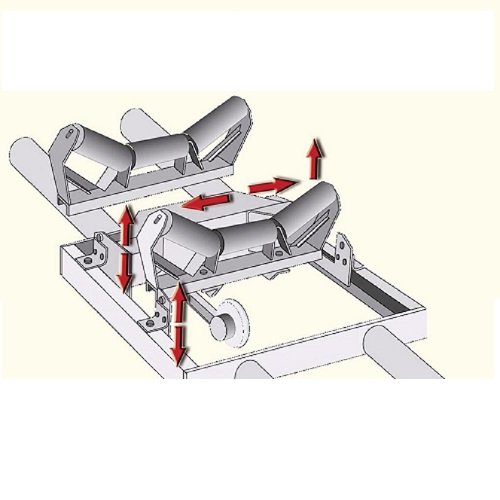

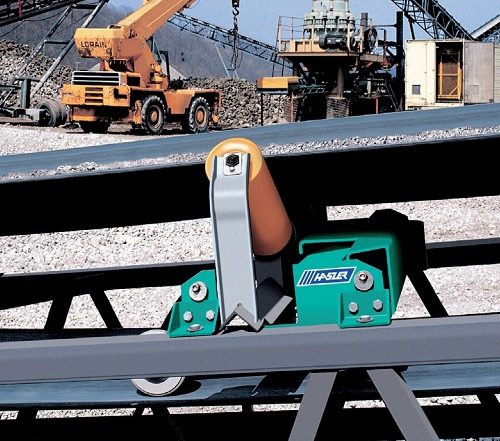

The Smart Bel Scale (SBS) is a conveyor belt scalee specially designed for rugged outdoor environment such as quarries, gravel processing and mining. It is also well suited for any manufacturing process using conveyor belts, including: cement, fertilizzer, chemical, tobacco, agro-food, etc. It is designed for easy installation which can be done by the customer’s own maintenance staff.

Product Highlight

Functions

- Weighing

- Flowrate calculation

- Totalization

- Dosing of all materials conveyed on a belt conveyor